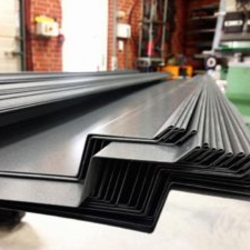

Through press brake bending, you can shape metal plates into components or brackets with specific angles and corners. In fact, you can minimize welding by bending or pressing a component instead of welding it, thereby reinforcing the structure. Metal plates are shaped using press tools, and applying substantial pressure ensures the desired angle for the component.

You can have the component laser-cut into any shape and then bent to achieve the exact desired form and angle.

Additionally, you can save on material thickness while maintaining a robust structure by opting for bending over welding.

We perform press breake bending for plates up to 3000mm with our 100-ton Guifil, but we can also bend components as small as a matchbox.

If you're uncertain whether press breake bending or welding is more suitable for your project, feel free to visit us with your drawings or ideas, and we'll find the solution that meets your needs.

Contact us for a non-binding quote regarding your project. We construct prototypes and produce series of components.

2239 9025 – ca@andersenssteel.dk